-

BIOACTIVATOR

BIOACTIVATOR -

Root

Root

Enhacer -

REDUCE DUST INCREASE SAFETY

REDUCE DUST INCREASE SAFETY

About Us

BIOGROW AUSTRALIA

BIOGROW AUSTRALIA is a member of the BIOGROW GROUP, incorporated in 2009 to supply premium nutrition and biostimulants to professional growers of fruit, vegetables and cereals. In addition BIOGROW offers a complete range of nutrients, coatings and additives to the seed treatment industry.

A New Agriculture

We develop innovative products which respect our environment.

We Are Experts

Our products have been developed from practical experience coupled with dedicated R&D.

Sowing the Future

We deliver safer and smarter technological solutions to help farmers pass on a sustainable and responsible stewardship of their land and Environment.

Featured Products

Products featured by our customers around the world.

physiogrow colour

physiogrow colourphysiogrow colour

physiogrow colourHigh Anthocyanin levels are responsible for the color in fruits. Deficiencies in macro and micro nutrients can impact plant energy, enzyme production which in turn impact anthocyanin production. PHYSIOGROW COLOR may help correct any nutrient deficiencies.

Aminostim

AminostimAMINOSTIM is the original and only amino acid product containing 19 synthesized free L-amino acids and oligo peptides of low molecular weight to treat plant stress. The unique formulation achieves fast absorption and does not tax a plant’s energy, whilst stimulating the transcription of genes and not interrupting its chlorophyll activity. Apply to improve flowering, fruitset, uniformity, colour, size, stress, vigour and overall plant health and vibrance.

Dowload label Dowload datasheet

CITOBLOOM ZIM

CITOBLOOM ZIMCITOBLOOM ZIM

CITOBLOOM ZIMDeficiencies in macro and micro nutrients can impact plant health such as shoots, flowers and fruit development. CITOBLOOM ZIM may help correct nutrient deficiencies.

KOPPREL 30 SL

KOPPREL 30 SLKOPPREL 30 SL

KOPPREL 30 SLKOPPREL 30 SL is a 100% soluble liquid fungicide, with a high concentration of Copper, to be applied via foliar spray or technified irrigation.

BUDBREAKER

BUDBREAKERBUDBREAKER

BUDBREAKERDeficiencies in Ca, N and other essential nutrients can impact new flower development. BUDBREAKER may help correct this deficiency.

VITALGROW

VITALGROWVITALGROW is a bioactivator used for foliar application, whose whole process involved in manufacturing allows to obtain a high quality product that provides plants with efficient and objective nutrition according to the needs of each crop.

BIOGROW MOL

BIOGROW MOLBIOGROW MOL

BIOGROW MOLBIOGROW MOL is a liquid formulation based on plant extracts and humic extracts, with a high content of Organic Matter (> 43%), composed of Organic Carbon, Humic Acids, Fulvic Acids, L-Amino Acids, Peptides and Sugars

BIOSTIM MZ

BIOSTIM MZBIOSTIM MZ is a foliar applied trace element corrector for manganese and zinc. The chelated properties allow the plant tissues to absorb it quickly with very high efficiency

BIOSTIM ZINC

BIOSTIM ZINCBIOSTIM ZINC

BIOSTIM ZINCBIOSTIM ZINC delivers the trace element zinc complexed with carboxylic acids. This insures plant tissues can absorb it quickly with very high efficiency. A pure and clean product compatible with many Ag chemicals. Well suited to foliar or seed dressing applications.

BIOSTIM POTASSIUM

BIOSTIM POTASSIUMBIOSTIM POTASSIUM

BIOSTIM POTASSIUMBIOSTIM POTASSIUM will address deficiencies in Potassium via foliar application. A high concentration of Potassium which is 100% complexed with carboxylic acids, allows plant tissues to absorb it quickly with very high efficiency.

BIOSTIM MAGNESIUM

BIOSTIM MAGNESIUMBIOSTIM MAGNESIUM

BIOSTIM MAGNESIUMBIOSTIM MAGNESIUM will improve deficiencies in Magnesium via foliar application. This premium magnesium complexed with carboxylic acids, allows plant tissues to absorb it quickly with very high efficiency.

BIOGLOSS LIQUID

BIOGLOSS LIQUIDBIOGLOSS LIQUID

BIOGLOSS LIQUIDBIOGLOSS Liquid is an additive specially developed to give a sophisticated, glossy and homogeneous finish to the seed coat. This innovative additive provides excellent flowability to the treated seeds. BIOGLOSS Liquid replaces the regular finishing powders used for this same purpose. Its addition, like powders, should be done soon after the application (dosing point) of the chemical treatment. It is not recommended to mix BIOGLOSS Liquid into the treatment slurry. BIOGLOSS Liquid does not significantly interfere in the drying process of seed treatment.

BIODRY

BIODRYBIODRY is a powder product whose objective is to complement the treatment of seeds by accelerating drying.

BIOGLOSS

BIOGLOSSBIOGLOSS is a product designed to complement seed treatment and deliver a shiny finish.

BIOCOR

BIOCOR

BIOCOR line consists of high concentration liquid pigment for seed treatment. They are products used with agrochemicals, which provide intense and uniform colors, as well as strengthening and improving the coloring effect of the treated seeds.

Download Label – Download Datasheet

BIOCOAT

BIOCOATBIOCOAT

BIOCOAT

BIOCOAT is a liquid polymer which reduces dust off from seed treatment. BIOCOAT will enhance the coverage and dispersion of seed treatment chemistry, accelerate drying, reduce chemical residues on equipment and insure a safer cleaner seed treatment operation. Available in red, blue, green,silver and colourless.

BENEFITS

- Dust Control

- Even chemical coverage

- OH&S – Reduced dust exposure, reduced operator exposure to chemical residues on equipment

- Fast drying – Improves flow through augers, no peaking in bins, free flowing seed

- Cleaner environment – less exposure for chemicals being washed into waterways

- Good Manufacturing Practice achieved

- Professional finish

- Protects active constituent

Download Label – Download Datasheet

BIOCOAT CORN

BIOCOAT CORNBIOCOAT CORN

BIOCOAT CORN

BIOCOAT® CORN is a liquid polymer which reduces dust off from corn / maize seed treatment. Given the unique characteristics for this seed variety, it is necessary to apply BIOCOAT® CORN to enhance the coverage and dispersion of seed treatment chemistry, accelerate drying, reduce chemical residues on equipment and insure a safer cleaner seed treatment operation. Available in red and blue for Australia.

BENEFITS

- Dust Control

- Even chemical coverage

- OH&S – Reduced dust exposure, reduced operator exposure to chemical residues on equipment

- Fast drying – Improves flow through augers, no peaking in bins, free flowing seed

- Cleaner environment – less exposure for chemicals being washed into waterways

- Good Manufacturing Practice achieved

- Professional finish

- Protects active constituent

Download Label – Download Datasheet

BIOCROMA

BIOCROMABIOCROMA

BIOCROMA

BIOCROMA® is the premium choice in reducing dust and achieving a brilliant seed treatment finish. Unmatched in seed flow and dust control properties BIOCROMA® will deliver the most professional finish in seed treatment.

Adding BIOCROMA® to the seed treatment recipe improves the movement of seed through seeders, and augers thus achieving accurate planting. Dust control is achieved by keeping the agchem on seed and removing the need for finishing powders (if used). Fast drying properties also add to the attractiveness of this premium additive to your seed treatment process.

BIOCROMA® has a great covering power, which makes it possible to completely change the appearance of the treatment color, regardless of the original color from the chemical treatment.

The BIOCROMA® Line is characterized by water-based formulated products to replace the use of post-finishing in seed treatment.

Its advanced technology gives an innovative result in seed coating.

Using BIOCROMA® consolidates all the advantages of using a finishing powder + polymer in a single formulation, allowing you to achieve sophisticated gloss, high quality coating and excellent appearance.

Available as Red and Silver in Australia. Well suited to canola seed and the treatment of high value crop types.

Download Label – Download Datasheet

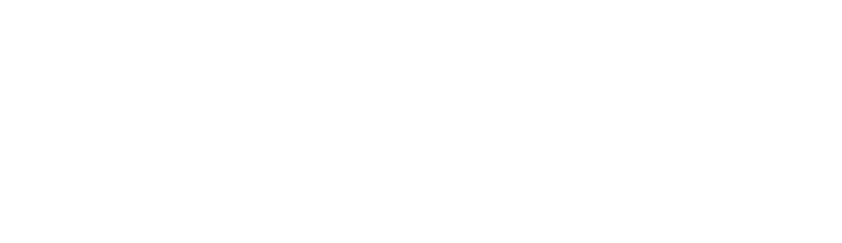

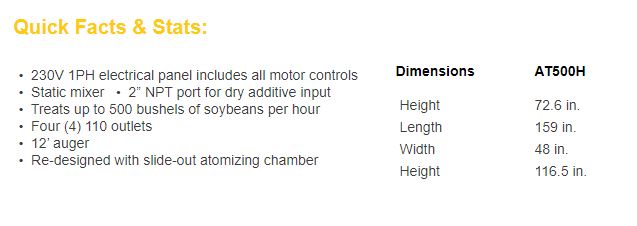

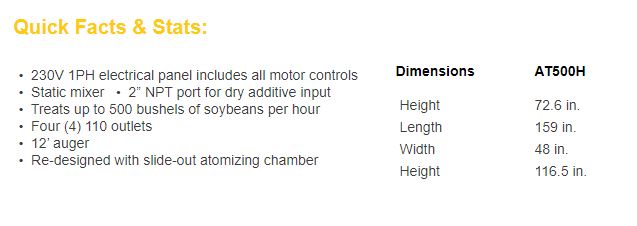

AT 500H

AT 500HAT 500H TREATER

Made in the USA by USC Seed Treating Solutions, the AT500H would have to be the most practical compact seed treater on the market. Cost effective, precision seed treatment. Many options available to customise to your operation. Poly flighted mixing and delivery auger is gentle on seed. Programable chemical treatment recipes utilising loss in weigh technology. Flexibility and innovation featuring USC’s patented slide out atomizer.

LP H800

LP H800– Escalado para tratar la semilla 136 360 kg por minuto.

– Tiene aerosol químico patentado de rotación para una distribución uniforme de agroquímicos, polímeros y otros tratamientos.

– Dispensación se produce a través de 2 bombas peristálticas de dosificación variable. Facilitación de la aplicación y de calibración, reduciendo la posibilidad de atascos, con mayores dosis de precisión y mantenimiento.

– Mezclador tanque de acero inoxidable de 133 litros de agroquímicos ya un inóculo de 56 litros, ambos con sistema de agitación lenta para mantener la homogeneidad de la solución.

– Función de vaciado Exclusivo, lo que facilita los procesos de limpieza y agiliza los cambios de configuración

| Especificaciones Equipo LPH800 | ||

| Especificaciones Técnicas | LPH 800 | Equipo Opcionales |

| Capacidad Operativa | Flujo continuo | |

| Tipo de Calibración | Manual Caudal Variable | |

| Tipo de Bombas | Cabezal Peristáltico | |

| Recipiente de calibración | SI / 10 litros | Flujo Masal |

| Atomizador | Rotativo de 13” | |

| Carga de Semillas | Flujo Ajustable | Seed Metering Wheel |

| Tipo de tanque Químicos | Integrado Inox 30 Gal. Mix Tank | Tanques adicionales para Inoculante |

| Alimentación | 230 Voltios monofásico | |

LPX 2000

LPX 2000– Permite el agregado de tanques y accesorios

– Innovadora tecnología de tratamiento por batch continuos

– Fácil acceso a la cámara de pulverización, simplificando la inspección y facilitando la limpieza y mantenimiento.

– Diseñado para tratar desde 136 a 816 Kg. de semilas por minuto

– Está totalmente automatizado, con almacenamiento de datos y pantalla táctil de 12”, pudiendo controlar en la versión estándar hasta 4 bombas de productos químicos, 1 de inoculante, 1 de producto en polvo y control de la cinta transportadora de entrada y salida de hasta 5 HP. Puede expandirse hasta 8 bombas de químicos.

– Está provista de impresora de reporte y puerto USB.

– Posee una rueda medidora de semillas

– Equipada con pulverizador patentado para dosificar los productos y recubrir uniformemente las semillas

– Cámara de pulverización deslizable para inspección, limpieza y mantenimiento.

– Sistema automático de dosificación de productos químicos líquidos por flujo o masal, de fácil calibración.

-Tanque de acero inoxidable de 113 litros a 226 litros.

– Sistema automático de dosificación de sólidos.

[embed]https://www.youtube.com/watch?v=iHzCFEQo6ME[/embed]LPX 2000 Portátil

LPX 2000 PortátilLPX 2000 Portátil

LPX 2000 PortátilPermite realizar toda la tecnología en el tratamiento de semillas de precisión, donde se requiere la actividad. Incluye un chasis para el retiro, la recepción silo, portador de la cinta de recepción, un equipo LPX 2000 y un transportador de salida de la correa.

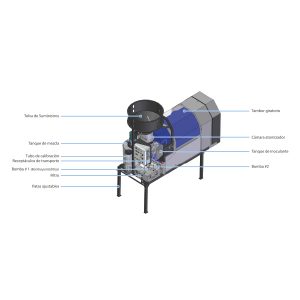

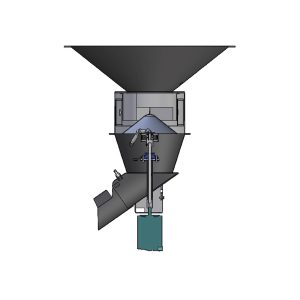

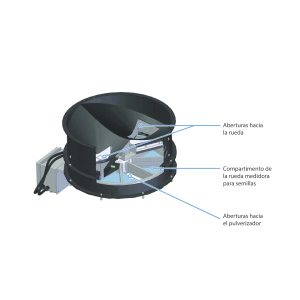

Rotary Atomizer

Rotary AtomizerRotary Atomizer

Rotary AtomizerEs un sistema patentado que diferencia el producto USC de los demás en el mercado.

Un componente esencial de la tecnología moderna y única en el tratamiento profesional, la obtención de una aplicación más uniforme de los grandes volúmenes de semillas procesadas por hora.

Seed Wheel

Seed WheelEste sistema de alimentación patentado por USC está diseñado para simplificar la calibración y ajuste del flujo de semillas, lo que permite el ajuste simultáneo de los equipos de bomba de cola.

Activa y captura cantidades idénticas de semillas en cada compartimento antes del tratamiento.

La rueda de medición, permite optimizar los tiempos de carga de semillas, lo que permite la entrega precisa de las semillas.

Tri Flo

Tri FloPermite el pesado de 800 kilos/minuto, siendo la combinación perfecta para alimentar a la LPX 2000 y optimizar la performance operativa de la planta de tratamiento de semillas.

[embed]https://www.youtube.com/watch?v=iHzCFEQo6ME[/embed]U BATCH

U BATCHU BATCH SEEDTREATER

The U-BATCH™ is one of the most versatile batch treaters on the market today. It is capable of treating most types of seed ranging from grass to soybeans. Its versatility is perfect for over-treatment, powder application or cover crop blending.

The capacity of the U-BATCH allows for handling up to one box or bag of seed. The compact design is a space saver making it easier to work this unit into any seed treating operation. The design is simple and efficient, giving a wide range of flexibility and application for seed treatment of almost any type of seed. Seed capacity ranges from 100 lbs to 2500 lbs per batch. Simple to operate, the U-BATCH™ can be managed through its automated 5.7″ HMI/PLC touch screen control. The operator has the ability to set the percentage motor speed for the vertical tapered screw and the on/off control from the touch screen. Power requirements are 230 volt, single phase. A discharge gate operates with an air actuated cylinder that is opened / closed from the touch screen. Continuous air pressure to the bottom of the treater chamber allows for a live bottom air seal.

NUTRITION

SEED TREATMENT

SEED TREATMENT EQUIPMENT

Colombia

Venezuela

Ecuador

Bolivia

Chile

Paraguay

Argentina

Uruguay

Southern NSW

Anthony Dichiera Sales Agronomist

anthony@biogrow.com.au

0419 250 192

Yarra Valley / Goulburn Valley

Geoff Jones General Manager

geoff@biogrow.com.au

0419168650

Sunraysia / Riverland

Anthony Dichiera Sales Agronomist

anthony@biogrow.com.au

0419 250 192

Tasmania

Geoff Jones General Manager

geoff@biogrow.com.au

0419168650

Colombia

Arsenio De la Torre

Managing Director

Venezuela

Arsenio De la Torre

Managing Director

Ecuador

Arsenio De la Torre

Managing Director

Bolivia

Arsenio De la Torre

Managing Director

Chile

Arsenio De la Torre

Managing Director

Felipe Diaz P.

CMO

Paraguay

Arsenio De la Torre

Managing Director

Evandro Marcus De Paula

Gerente Zonal Latam

Argentina

Arsenio De la Torre

Managing Director

Juan Petri

General Manager Argentina

Uruguay

Arsenio De la Torre

Managing Director